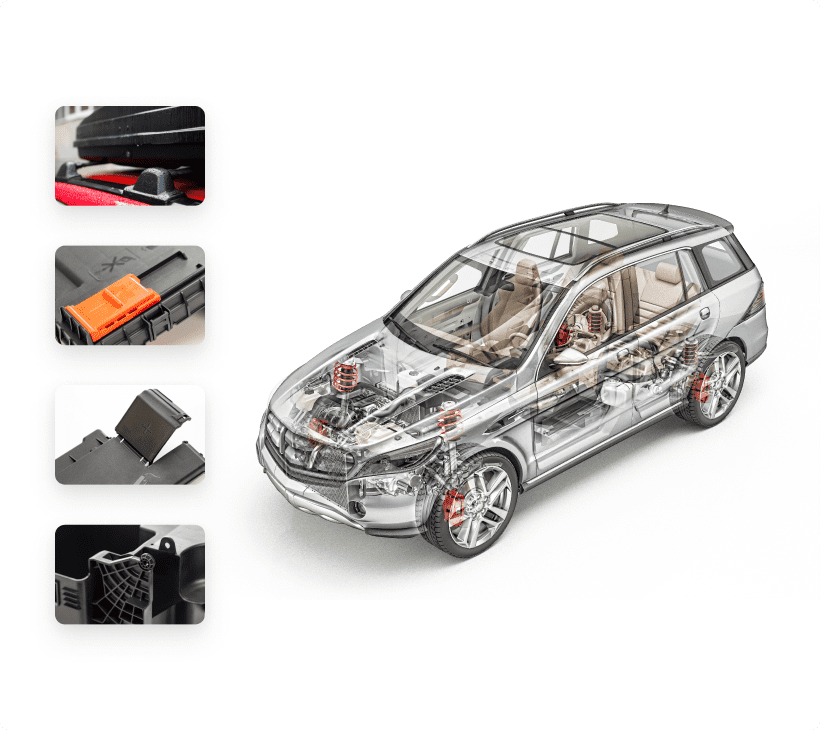

Materials for Automotive Interior, Exterior and Underhood—We’ve Got You Covered.

Materials and Design Engineers at both OEMs and Tiers trust GEON to supply materials that meet product specifications for global regulatory needs. For the successful design and manufacture of vehicle components that enhance quality and performance, you need a supplier that understands your goals, not just for today, but for the future.

With GEON, you’ll find our manufacturing footprint, throughout North America, and close to the molder base, is a distinct competitive advantage to our customers in cost reduction and risk mitigation.

An established automotive supplier with widely used and accepted compounds - tour candidate materials for interior, exterior and underhood applications.

- Instrument Panel Retainers - sub-structure for the IP where high material strength and stiffness is needed

- Floor Console Retainers - sub-structure requiring strength, stiffness and dimensional accuracy

- Load Floors (Flipper Panel)/Seat Backs - provides structural component when reconfigured in vehicle

- Interior Panels and Storage Compartments - Best-in-Class Scratch and Mar TPO with Enhanced Impact Resistance

- Multiple material offerings to support HVAC housings and internals with various reinforcement types and levels for optimum performance

- Fan Shrouds - Black Glass- and Talc- filled HPPP

- Engine Covers - Mineral- and/or Glass-Filled PP

- Air Filtration (Housings) 2-piece design PP for top and bottom

- Power Distribution Boxes, Battery and Fuse Box/Cover - PP products to protect vital componentry and with the ability for decorative or labeling processes.

- TPO and PP compounds for Cowl Screens, Air Deflectors, Underbody Shields, Aero Add-Ons and Running Boards

our TPEs combine excellent sealing properties, durability, chemical resistance, and temperature stability to provide automotive designers with a lightweight, cost-effective replacement for PVC and other rubber materials for many applications including:

- Body Seals

- Floor Mat

- HVAC

- Glazing Seals

- Coated Fabric

- Boot/Bellows

- Interior – Skins

- Airbag Covers

- Gaskets

-

- Instrument Panel Retainers - sub-structure for the IP where high material strength and stiffness is needed

- Floor Console Retainers - sub-structure requiring strength, stiffness and dimensional accuracy

- Load Floors (Flipper Panel)/Seat Backs - provides structural component when reconfigured in vehicle

- Interior Panels and Storage Compartments - Best-in-Class Scratch and Mar TPO with Enhanced Impact Resistance

-

- Multiple material offerings to support HVAC housings and internals with various reinforcement types and levels for optimum performance

- Fan Shrouds - Black Glass- and Talc- filled HPPP

- Engine Covers - Mineral- and/or Glass-Filled PP

- Air Filtration (Housings) 2-piece design PP for top and bottom

- Power Distribution Boxes, Battery and Fuse Box/Cover - PP products to protect vital componentry and with the ability for decorative or labeling processes.

-

- TPO and PP compounds for Cowl Screens, Air Deflectors, Underbody Shields, Aero Add-Ons and Running Boards

-

our TPEs combine excellent sealing properties, durability, chemical resistance, and temperature stability to provide automotive designers with a lightweight, cost-effective replacement for PVC and other rubber materials for many applications including:

- Body Seals

- Floor Mat

- HVAC

- Glazing Seals

- Coated Fabric

- Boot/Bellows

- Interior – Skins

- Airbag Covers

- Gaskets

Materials you can Trust to Deliver on Performance Requirements

Select the materials that deliver the most value to your operation, ensuring everything runs smoothly during the manufacturing process. Maximize the potential of your parts with technical and design support.

Superior Rheology

High Melt Flow Rate (MFR) - Material flows better and the tool can fill the cavity easier, resulting in faster cycle times and dimensional performance

High Stiffness

Above 2700 MPA (Megapascal) flex modulus for load-bearing parts such as instrument panels

High Ductility

Energy management grades provide cold temperature ductility for interior applications

Thermal Management

High Heat Deflection Temperature (HDT) performance for underhood applications, providing durability and thermal stability

Ease of Color

Natural base colors that are easily mixed with color concentrate saving on time, money, scrap and offers material management options

Lightweighting

Thinner, stronger materials that use lower density, or lower specific gravity materials with added talc or fiberglass

High Strength

High strength materials for impact sensitive applications

Green Materials

Range of functional black parts with recycled PP bringing RC to the vehicle, help meet sustainability targets

Customer Satisfaction

Hard plastic parts - scratch and mar resistance for interior applications, providing long term ownership satisfaction

Looking for a specific material?

Uniquely Positioned to Serve the Automotive Industry from Cradle-to-Grave

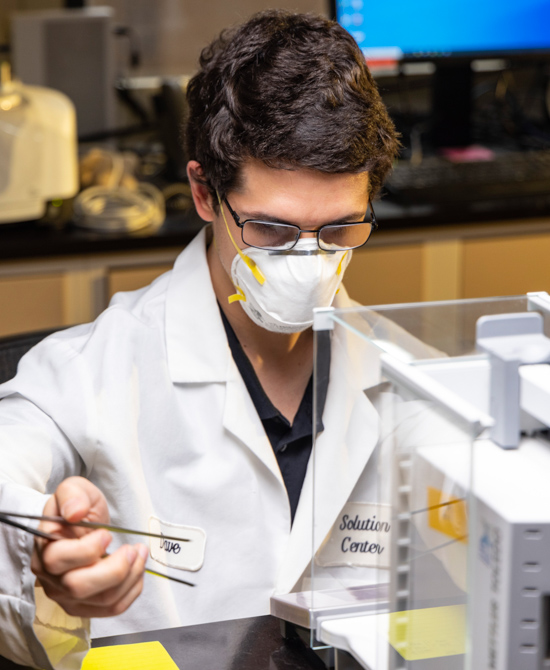

GEON is with you, every step of the way through your material selection and part design journey. With advanced R&D and product formulations, our application development engineering team often provides process support to customers.

Our customers have access to dedicated resources. Our auto subject matter experts have collective decades of experience in the auto industry. You can rest assured that you’ll be partnered with the specialists that drive towards solutions, not generalists you have to catch up to speed.

Product Development

- Provide OEM or Tier specification approval submission support

- Develop materials to market needs or customer requirements

- Lab samples upon request

Part Design

- Provide application, product design support

- Consultation on mold design ensuring quality parts

Optimal Process

- On-site technical engineering support available

- Production startup and process optimization

- Ongoing manufacturing problem resolution

Sustainability Through Innovation – Turning Recycled Plastics into Cars

Post-industrial recycled (PIR) and post-consumer recycled (PCR) materials are being rapidly adopted to make new car parts in vehicles.

When approving a resin, you require a consistent, quality supply. GEON has a variety of products containing reclaimed materials and a long history with PCR and PIR content, going back over two decades.

There are Many Innovative Ways to Meet Your Sustainability Goals

35%

Reprocessed materials available with up to 30% Recycled Content

Featured Materials

Sorry!

No items currently match your filtering criteria.

GEON® in The World

Behind every manufacturing advance made possible by GEON’s technology and services is a story about collaboration and innovation.