- Materials

- Polyolefins

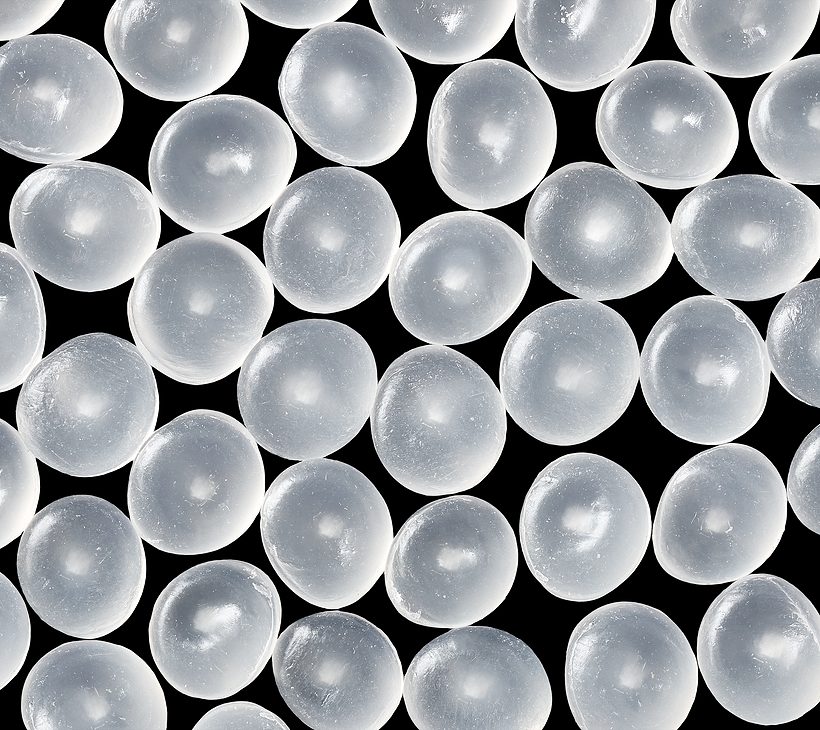

Innovate with Polypropylene (PP) and Thermoplastic Polyolefin Elastomer (TPO) Materials

Whether your market application is auto underhood, door sweepers, profiles on window inserts, or components in large appliances, GEON® RESILIENCE® PP and RESILIENCE® TPO are designed to meet stringent applications.

Through collaboration with our customers, we have developed unique solutions that foster product differentiation and enable speed to market. Our skilled technical teams bridge the gap between material sciences and application engineering to include tool design and efficient processing techniques.

Robust, Targeted and Optimized New Product Introductions

Access proven application development for PP, TPOs and other engineered polymeric systems. Partnering with our industry trained professionals, you’ll experience an efficient product development cycle with innovative compounds.

- Meet regulatory guidelines and reduce complexity with preapproved portfolio for specific applications

- Design for manufacturability from conceptualization to actualization, quick turnaround programs to speed product development cycle and reduce iterations

- Add unique features including extended performance to minimize risk and emphasize product differentiation

You’ll find that GEON plants are advantageously situated near your operation. Our plants allow for a shorter timeframe to obtain materials and deliver compounds to our customers.

Our manufacturing facility in Ramos Arizpe, Mexico delivers a distinct advantage to automotive OEMs that don’t have to wait for products from the U.S.

We help customers achieve their sustainability goals through inclusion of PCR and PIR materials. We have a proven ability to address the inherent inconsistencies and impurities of repro and the formulary expertise to deliver a consistent product that is comparable to prime.

By expanding the design envelope of PP, with advanced additive technologies and filler systems, we offer our customers sustainable alternatives to promote responsible choice.

RESILIENCE R polyolefins are reengineered within the specification with recycled content for desired product attributes, delivering long-term performance and value.

-

Access proven application development for PP, TPOs and other engineered polymeric systems. Partnering with our industry trained professionals, you’ll experience an efficient product development cycle with innovative compounds.

- Meet regulatory guidelines and reduce complexity with preapproved portfolio for specific applications

- Design for manufacturability from conceptualization to actualization, quick turnaround programs to speed product development cycle and reduce iterations

- Add unique features including extended performance to minimize risk and emphasize product differentiation

-

You’ll find that GEON plants are advantageously situated near your operation. Our plants allow for a shorter timeframe to obtain materials and deliver compounds to our customers.

Our manufacturing facility in Ramos Arizpe, Mexico delivers a distinct advantage to automotive OEMs that don’t have to wait for products from the U.S.

-

We help customers achieve their sustainability goals through inclusion of PCR and PIR materials. We have a proven ability to address the inherent inconsistencies and impurities of repro and the formulary expertise to deliver a consistent product that is comparable to prime.

By expanding the design envelope of PP, with advanced additive technologies and filler systems, we offer our customers sustainable alternatives to promote responsible choice.

RESILIENCE R polyolefins are reengineered within the specification with recycled content for desired product attributes, delivering long-term performance and value.

Choose RESILIENCE to Meet your Specific PP and TPO Materials Requirements

Custom compounds in natural, black or pre-colored that can be injection molded, blow molded or extruded. Whether it’s high strength, high impact, UV stabilized or scratch and mar resistance - RESILIENCE delivers the performance you need.

Lightweighting

Lighter and stronger materials

Aesthetics

Lots of colors for design freedom

Customized Products

Tailored to meet your needs

Agency Approvals

Long-term technical relationships with UL and NSF

Reinforcement

Talc, Glass, Calcium Carbonate, Mica - different filler levels, high RTI ratings

Custom Compounder

Broad industry experience and knowledge transfer

Certified

All plants ISO 9000 certified

IATF

Automotive certified plants

Looking for a specific material?

Featured Materials

Sorry!

No items currently match your filtering criteria.