- Materials

- Product Brands

- RESILIENCE®

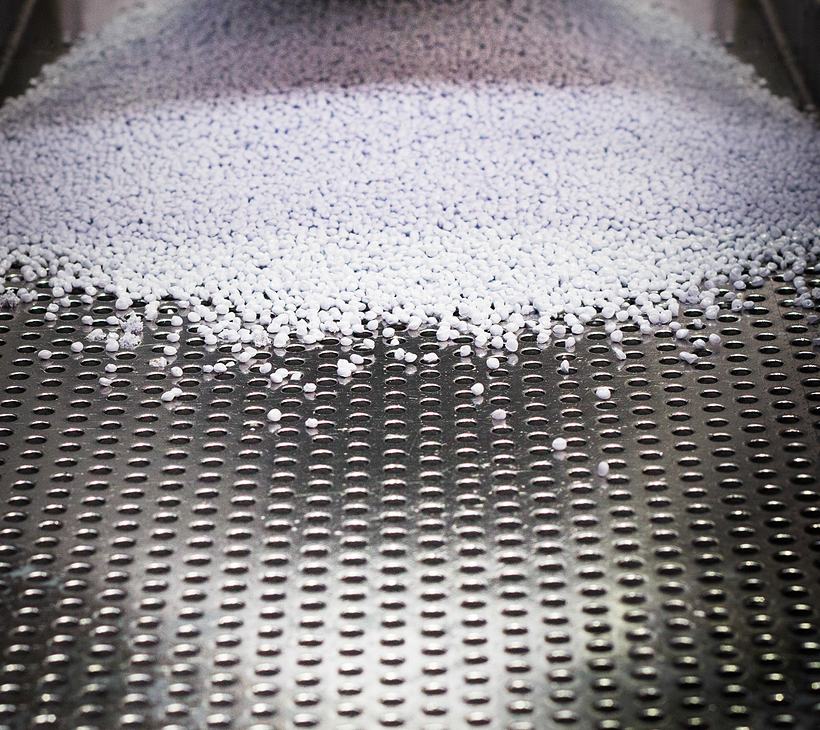

Introducing GEON® RESILIENCE® Filled & Reinforced Polyolefin Systems

A range of proven polyolefins for injection molding, blow molding and extrusion - choose the RESILIENCE product that’s right for your application. If custom solutions are required, engage our technical experts for product development, part design and process optimization.

Polyolefins Products Designed for Stringent Market Needs

GEON RESILIENCE® polyolefins offers a comprehensive line of UL listed high performance compounds.

Tour The Product That Meets Your Specification

Polypropylene compounds formulated with calcium carbonate, glass, mica and talc to provide a desired balance of properties, including stiffness, durability, impact resistance, dimensional stability and heat resistance.

Thermoplastic Polyolefins grades that offer an exceptional balance of stiffness and impact performance, even in cold temperatures.

Polyolefin grades with minimum standard levels of Recycled Content (RC) to meet your sustainability goals.

High Strength reinforced grades that provide excellent stiffness.

TPO grades with exceptional stiffness and impact balance, including superior cold temperature impact resistance/ductility.

Low Odor talc-filled grade that reduces volatile organic compounds (VOCs) and emission with inherent heat stabilization and customizable physical property balance.

-

Polypropylene compounds formulated with calcium carbonate, glass, mica and talc to provide a desired balance of properties, including stiffness, durability, impact resistance, dimensional stability and heat resistance.

-

Thermoplastic Polyolefins grades that offer an exceptional balance of stiffness and impact performance, even in cold temperatures.

-

Polyolefin grades with minimum standard levels of Recycled Content (RC) to meet your sustainability goals.

-

High Strength reinforced grades that provide excellent stiffness.

-

TPO grades with exceptional stiffness and impact balance, including superior cold temperature impact resistance/ductility.

-

Low Odor talc-filled grade that reduces volatile organic compounds (VOCs) and emission with inherent heat stabilization and customizable physical property balance.

Meet The Performance Demands of Your Specific Application

GEON RESILIENCE formulations incorporate the latest in polymer modification, additive and process chemistry, and offer ease of processing in most standard thermoplastic equipment.

UL94 HB Approved

FDA Certifiable

Natural, Black or Colors

High Flow Grades

UV Stabilized

Post Industrial Recycled (PIR) Content

Chemically Coupled

Impact Modified

Scratch and Mar Resistant

Heat Stabilization

Balance of Properties

Access Best-in-Class Recycled Material Utilization in Filled & Reinforced PP Systems

Spotlight on RESILIENCE® R Polypropylene

From homopolymer, copolymer to impact modified, our UL94 HB approved polypropylene, formulated with minimum standards of recycled content are the ideal selection to meet your sustainability goals.

Filled or Reinforced PP – It’s What We Do.

40%

Talc, Calcium Carb, Mica, Glass Fiber & Barium Sulfate filler up to 40%

35%

Minimum RC levels up to 35%

Featured Materials

Sorry!

No items currently match your filtering criteria.

Looking for a specific material?

GEON® in The World

Behind every manufacturing advance made possible by GEON’s technology and services is a story about collaboration and innovation.