- Materials

- Product Brands

- GEON® Fiberloc™ Composites

GEON® Fiberloc™ Composites

Technology Designed for Both Injection Molding and Extrusion Applications

Fiberloc™ Optimal and Fiberloc™ Extreme™ composites have proprietary low wear technology that provides up to 50 percent reduction in wear versus traditional glass composites.

Design Stronger, More Durable, Lighter Weight Components While Reducing Your Energy and Product Lifecycle Costs.

Increase your competitive advantage by using parts made from PVC Composite

Other engineered thermoplastics may meet your strength and stiffness requirements but aren’t designed for extrusion. GEON Fiberloc™ Optimal™ and Extreme™ composites are designed to meet your exact product specifications without damaging your equipment. Either grade can be easily drilled, cut or machined on standard equipment or joined by standard welding techniques.

Reduction in Wear

Results in up to a 50 percent reduction in wear versus traditional glass composites – extending equipment life and increasing productivity

Efficiency & Performance

Exceptional strength-to-weight ratio for improved efficiency and cost savings

Increased Heat Distortion Temperature (HDT)

Corrosion and fatigue resistance, even under extreme temperatures, for longer product life

Thermal Stability

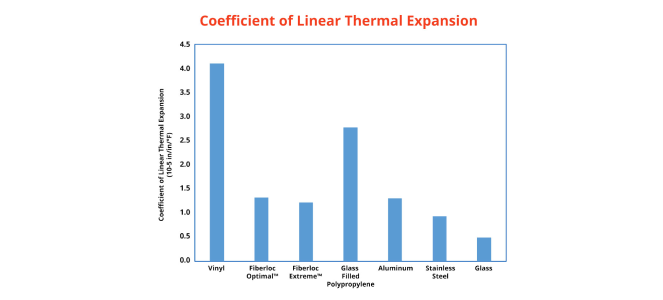

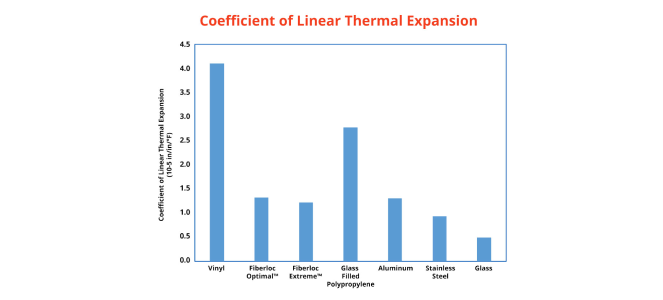

Low coefficient of linear thermal expansion (CLTE) suitable for applications subjected to hot/cold cycles

Design Freedom

Enables unlimited lengths and design capabilities for easier part consolidation and lower assembly costs

EXCEPTIONAL STRENGTH-TO-WEIGHT RATIO = IMPROVED EFFICIENCY, COST SAVINGS

Fiberloc Composites can have up to 75% lower specific gravity than steel and up to 25% lower specific gravity than aluminum, replacing less energy-efficient materials without compromising performance.

75%

lower specific gravity than steel

Up to 25%

lower specific gravity than aluminum

Increased Processability and Loading

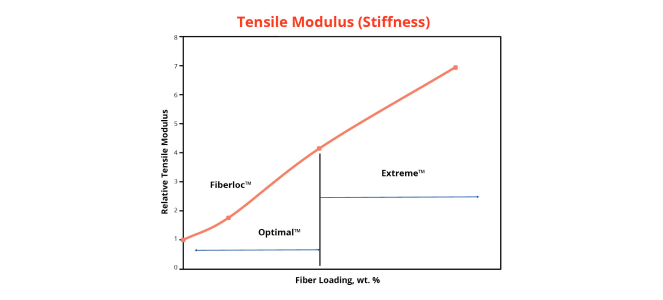

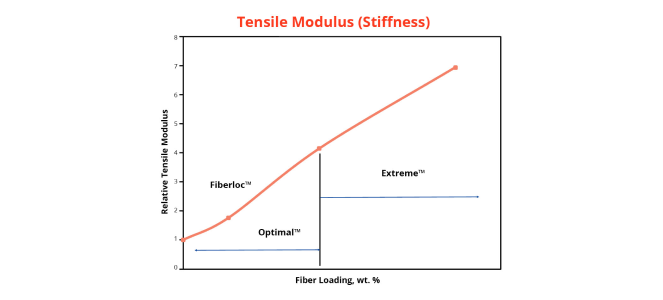

- Fiberloc™ Optimal™ Products: tensile modulus up to 1000 ksi

- Fiberloc™ Extreme™ Products: tensile modulus higher than 1000 ksi

- Fiberloc™ composites exhibit low coefficient of linear thermal expansion (CLTE) suitable for applications subjected to hot/cold cycles

- Fiberloc™ composites can achieve CLTE comparable to aluminum

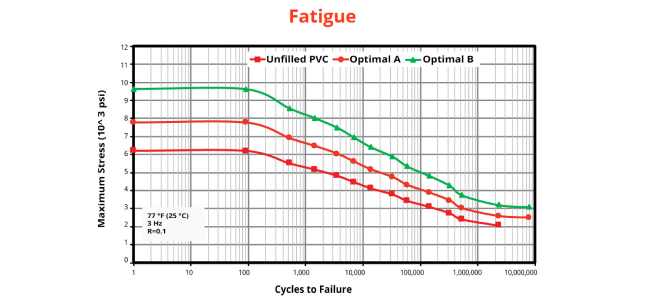

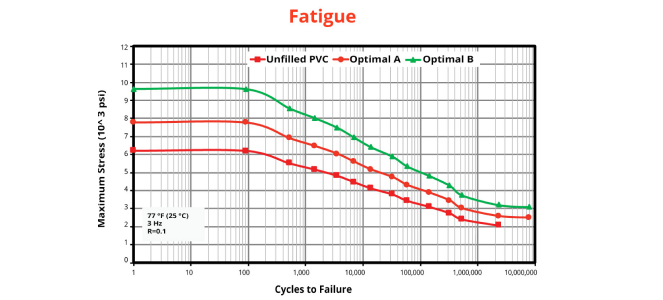

- Glass fiber reinforcement can improve the ultimate tensile strength of the vinyl matrix, which is maintained over the entire cycling range out to a million cycles

- The composites with higher loading of fiber content exhibit better fatigue resistance

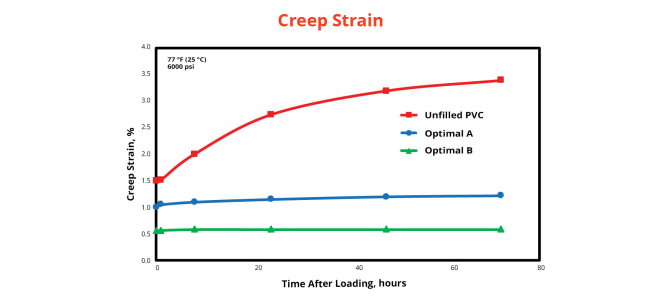

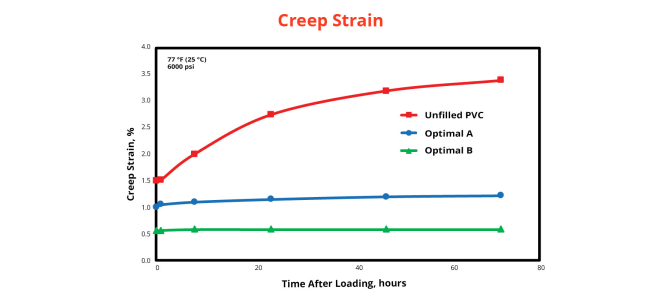

- Fiberloc™ composites show excellent resistance to deformation under high loads over extended periods of time

- Resistance to deformation improves with increasing fiber loading

-

- Fiberloc™ Optimal™ Products: tensile modulus up to 1000 ksi

- Fiberloc™ Extreme™ Products: tensile modulus higher than 1000 ksi

-

- Fiberloc™ composites exhibit low coefficient of linear thermal expansion (CLTE) suitable for applications subjected to hot/cold cycles

- Fiberloc™ composites can achieve CLTE comparable to aluminum

-

- Glass fiber reinforcement can improve the ultimate tensile strength of the vinyl matrix, which is maintained over the entire cycling range out to a million cycles

- The composites with higher loading of fiber content exhibit better fatigue resistance

-

- Fiberloc™ composites show excellent resistance to deformation under high loads over extended periods of time

- Resistance to deformation improves with increasing fiber loading

Featured Materials

Sorry!

No items currently match your filtering criteria.

GEON® Fiberloc™ Composites Are Ideal for These Market Applications