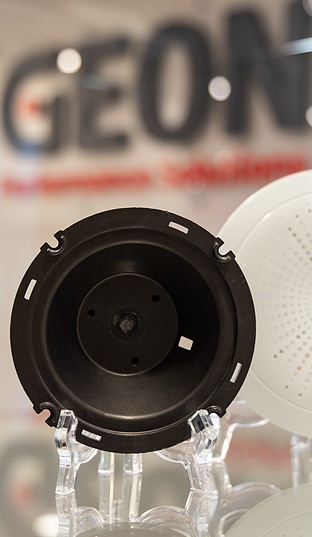

Outsource PVC Compounding to GEON and Gain Competitive Advantage

Our strategic manufacturing services are designed to help innovate across your business, optimize operations and get to market faster. Whether you need technical recommendations for selecting the right material or regulatory guidance, however you choose to partner with us, you can always expect competency and reliability.

Full-Spectrum Manufacturing Services from a Top PVC Compound Producer

As experts in polymer compounding and process technology, with an industry-leading formulation library developed over 100 years, we know a thing or two about PVC compounds.

These are some of the challenges that companies have avoided by outsourcing to GEON:

- Compound dimensional stability not optimized to production machinery

- Outdated technology and inefficient equipment

- Downtime and low asset utilization

- Regulatory issues and high agency costs

- Resource constraints with lack of access to technicians and engineers

Material, compound conversion costs and administration are brought to zero while simplifying your business. You can also:

- Reduce carrying costs and increase line speed

- Gain benefits in throughput, scrap and inventory reduction

- Minimize downtime and low asset utilization

- Remove the need to purchase new compounding assets

- Realize benefit from potential sale of compounding assets

With unrivaled manufacturing and processing flexibility, expertise in polymer formulation and top machinery with high throughputs, it’s easy to choose GEON as your compounding partner. Our customers experience:

- Automated processes linked to ERP and financial data systems

- Rail access at most facilities

- Diverse set of on-site packaging options

All with supply chain services including direct shipments to OEMs.

-

As experts in polymer compounding and process technology, with an industry-leading formulation library developed over 100 years, we know a thing or two about PVC compounds.

These are some of the challenges that companies have avoided by outsourcing to GEON:

- Compound dimensional stability not optimized to production machinery

- Outdated technology and inefficient equipment

- Downtime and low asset utilization

- Regulatory issues and high agency costs

- Resource constraints with lack of access to technicians and engineers

-

Material, compound conversion costs and administration are brought to zero while simplifying your business. You can also:

- Reduce carrying costs and increase line speed

- Gain benefits in throughput, scrap and inventory reduction

- Minimize downtime and low asset utilization

- Remove the need to purchase new compounding assets

- Realize benefit from potential sale of compounding assets

-

With unrivaled manufacturing and processing flexibility, expertise in polymer formulation and top machinery with high throughputs, it’s easy to choose GEON as your compounding partner. Our customers experience:

- Automated processes linked to ERP and financial data systems

- Rail access at most facilities

- Diverse set of on-site packaging options

All with supply chain services including direct shipments to OEMs.

Solutions that Fit Your Needs with Seamless Integration into Your Business

Short-term engagements

For surprise plant upsets or planned expansions

Turnkey manufacturing

To complement your capability or allow you to exit manufacturing

Manufacturing Services

Including batch and continuous mixing, reactive extrusion, pilot-scale mixing, blending, drying and packaging

Capital Efficiency

Avoid costs of technology upgrades and capacity expansion, optimize direct and indirect labor, eliminate/reduce maintenance and improve efficiency

Top Industry Personnel

Access to industry experts, creative problem-solving, trial and scale-up expertise and deep experience

Sustainability

Commitment to continually improving the efficiency and sustainability of our operations

Total Cost Control

Global buying power, single cost center, inventory management, price stability

World-Class Quality

Continuous improvement, ISO certified facilities, advanced regulatory capability

End-to-End Manufacturing

Pilot capability, multiple locations, millions of pounds of capacity, state-of-the-art facilities

Collaborative Project Management from Industry Professionals

- Lean Six Sigma certified with 11 employees dedicated as Black Belts

- Multiple LSS program awards from “Process Excellence Network”

- On-site, cross-company KAIZEN™ events